charpy impact test cooling|charpy impact chart : bespoke Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact . webDuskwood. Duskwood é um jogo para celular disponível para Android e iOS. Este é um jogo de suspense onde os personagens interagem diretamente com você simulando uma conversa estilo Whatsapp. Este .

{plog:ftitle_list}

WEBTiny Toon Adventures: Created by Alan Smart. With Charlie Adler, Tress MacNeille, Joe Alaskey, Don Messick. The wacky adventures of the new young hip generation of .

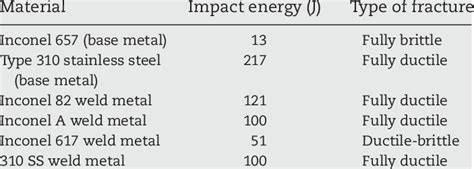

Some materials, upon cooling below a critical temperature, will exhibit a rapid decrease in their measured impact toughness. This change is called a ductile to brittle transition (DTBT). Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact .The impact strength (also referred to as notched impact strength) is determined through Charpy testing, and provides information on how resistant a material is to an impact load, or how well a material can handle an impact without breaking.Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .

charpy impact test temperature requirements

charpy impact test sample

The Charpy test is a standardized procedure designed to measure the energy absorbed by a material during a sudden impact load. This evaluation method assesses the material's .In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a .

The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures!

Material impact toughness can be measured by various types of test such as the Charpy V-notch impact test, Izod test or K IC test. The most commonly used test is the Charpy impact test .

Charpy impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact event as well as the failure mode can be tested. The specimen is usually in the form of a thick beam with or without a notch and is supported freely at two ends, as shown in Fig. 3 (a).Product Description. BDCW-100 refrigerating Bath | cooling thermostatic bath | cryogenic tank for charpy notch impact test is a compressor refrigeration device developed by BuenoBiotech according to the requirements for cryogenic tank .Low temperature Chamber for Impact Specimen is designed according to Charpy notch Impact Test Method for Metal Material, and adopts compressor cooling technology. It utilizes the heat balance principle and cycle stirring .

The objective of the Charpy impact test to ISO 148-1 is the determination of the impact energy and determination of the impact strength of a metal. The test indicates whether the metal is tough or brittle. In addition, the tough/brittle transition can be determined based on the temperature. Impact strength is a material characteristic value.

The Class D Metals Impact Tester is a Single column impact testing system designed for Charpy Impact testing according to ASTM E23, ISO 148 and EN10045 industry standards. The Class D has has two popular models with peak capacities of 450J and 750J with optional pendulums for 150J, 300J, 450J and 600J.The machine is equipped with optional sample feeding equipment and a cooling chamber for the automatic and safe completion of tests. Additionally, the system can be upgraded to an instrumented pendulum impact tester, complying with ISO 14556 standards for enhanced precision. . Benefits of Charpy Impact Testing for Material Toughness.Plastic Charpy impact testing (ASTM D256) Miniature Charpy pendulum impact testing (ASTM E2248) Beverage can impact testing. Options. . In-situ heating & cooling system. Automatic specimen transfer system. Image analysis system for percent shear determination. Energy And Impact Velocity. Two different ultra-high-strength B-containing steel strips, one treated with Ti and the other treated with Al, processed by controlled rolling, accelerated cooling, and coiling in two different temperatures ranges (450 °C to 460 °C and 360 °C to 380 °C) were subjected to tensile testing, bend testing, and Charpy impact testing. The relatively softer and homogeneous .

The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test which determines the amount of energy absorbed by a material during fracture. This absorbed energy is a measure of a given material's notch toughness and acts as a tool to study temperature-dependent ductile-brittle transition.The indirect verification of Charpy machines was added to ASTM E23 more than 50 years ago as a means to reduce the scatter of Charpy test results and ensure the correct operation and maintenance of impact machines [2]. The U.S. Army (Watertown Arsenal, Advanced Manufacturing and Mechanical ReliabilityQuiz yourself with questions and answers for Charpy Impact Test, so you can be ready for test day. Explore quizzes and practice tests created by teachers and students or create one from your course material. . What cooling media are used in the charpy hardness testing? What heating media are used? 300 +/- 10 Joules Testing machines with lower .

charpy impact test pdf

In this study, four API X80 linepipe steel specimens were fabricated by varying the cooling rate and finish cooling temperature, and their microstructures and crystallographic orientations were analyzed to investigate the effects of the cooling conditions on the tensile and Charpy impact properties. All the specimens consisted of acicular ferrite (AF), granular .

MP Machinery and Testing manufactures the most accurate Charpy impact test machines in the world and offers testing, research, and consulting services. Home About Nuclear Solutions . The Heating/Cooling system can configured in two ways: Batch Mode (for high specimen throughput) or Single Specimen Mode. In the Batch Mode, a thermal .The MPM Charpy/Izod 9000 Series impact test machines can be used with pendulums in the 100 ft-lb to 700 ft-lb energy capacity range. Since the machine frame has been designed for up to 700 ft-lbs, any lower capacity can be accommodated. . In-situ heating & cooling system (In-situ Heating & Cooling) Automatic specimen transfer system .

Impact Testing – Charpy and Izod Tests. The impact testing method is pivotal for determining a material’s ductile-to-brittle transition temperature and its ability to resist deformation due to impact loads. These .

Our award winning Charpy Machines - The Powerful MPM Pendulum 9000 Test Machines coupled with our proprietary patented and unparalleled In-situ Heating & Cooling System technology, our automated high throughput specimen transfer system, our Charpy technology, allows us to provide you with unmatched quality and reliability of impact testing in .MPM manufactures drop tower test machines for a wide variety of impact tests. The MPM drop tower systems can be configured to satisfy several ASTM standards including: ASTM E23, E208, E436, D3763, D256, D2444, and D6110.Introduction to Charpy Testing Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to measure a material’s notch toughness at moderately high strain rates. It is defined by the ASTM . Some materials, upon cooling below a critical temperature, will exhibit a rapid decreaseProduct Description. BDCW-80 refrigerating Bath | cooling thermostatic bath | cryogenic tank for charpy notch impact test is a compressor refrigeration device developed by BuenoBiotech according to the requirements for cryogenic tank of impact test in《GB/ t229-2007 charpy notch impact test method for metallic materials》.

.the right impact test equipment for standard-compliant testing! Impact testers help determine the failure behavior of materials or components under rapid loads and changing temperatures. Because many materials used for a number of different applications on a daily basis are subjected to fluctuating temperatures, and since the fracture or failure behavior also depends on .The Charpy impact test was invented in 1900 by Georges Augustin Albert Charpy (1865–1945), and it is regarded as one of the most commonly used test to evaluate the relative toughness of a material in a fast and economic way. The Charpy impact test measures the energy absorbed by a standard notched specimen while breaking under an impact load. This test continues to be .DWC-40 Charpy Impact Test Cooling Low Temperature Chamber / Impact Sample Freezer. ,400.00-,500.00. Min. Order: 1 set. Previous slide Next slide. Charpy impact test sample cooling furnace low temperature chamber LIANGONG electronic. ,600.00. Min. Order: 1 set. Previous slide Next slide.The Charpy impact and notched impact test to ISO 179-1 and ISO 179-2 provide characteristic values for impact strength at high strain rates in the form of an area-related energy value. The tests are normally performed in normal climate or at low temperatures. Applications include: The comparison of different molding materials

For testing at low temperatures the specimens are first conditioned in a cooling box. The magazine with the specimens is then attached to the specimen feeder, which is fastened to the HIT pendulum impact tester. . Metals | Notched specimen impact test Charpy. ISO 148-1. to Metals | Notched specimen impact test Charpy Downloads. Name Type Size .The MPM CC/DTB reaches cold setpoints faster because it uses liquid nitrogen as a coolant for tests that are conducted below room temperature. . The standard system contains up to 63 Charpy impact test specimens. The Charpy specimen holders can be easily removed and replaced with dynamic tear (DT) specimen holders. . Six ultra-low-carbon high-strength bainitic steel plates were fabricated by controlling rolling and cooling conditions, and effects of bainitic microstructure on tensile and Charpy impact properties were investigated. The microstructural evolution was more critically affected by start cooling temperature and cooling rate than by finish rolling temperature. .The results show that evaporative cooling causes significant changes in the specimen temperatures when water is used for conditioning. Conditioning in the other media did not result in such significant changes. . significant test temperature changes can occur which may substantially affect the Charpy impact test results if water is used for .

webCaixa Econômica Federal. 4.4 star. FGTS

charpy impact test cooling|charpy impact chart